In modern manufacturing industry, efficient and precise supply of materials is one of the key factors to ensure production efficiency and product quality.

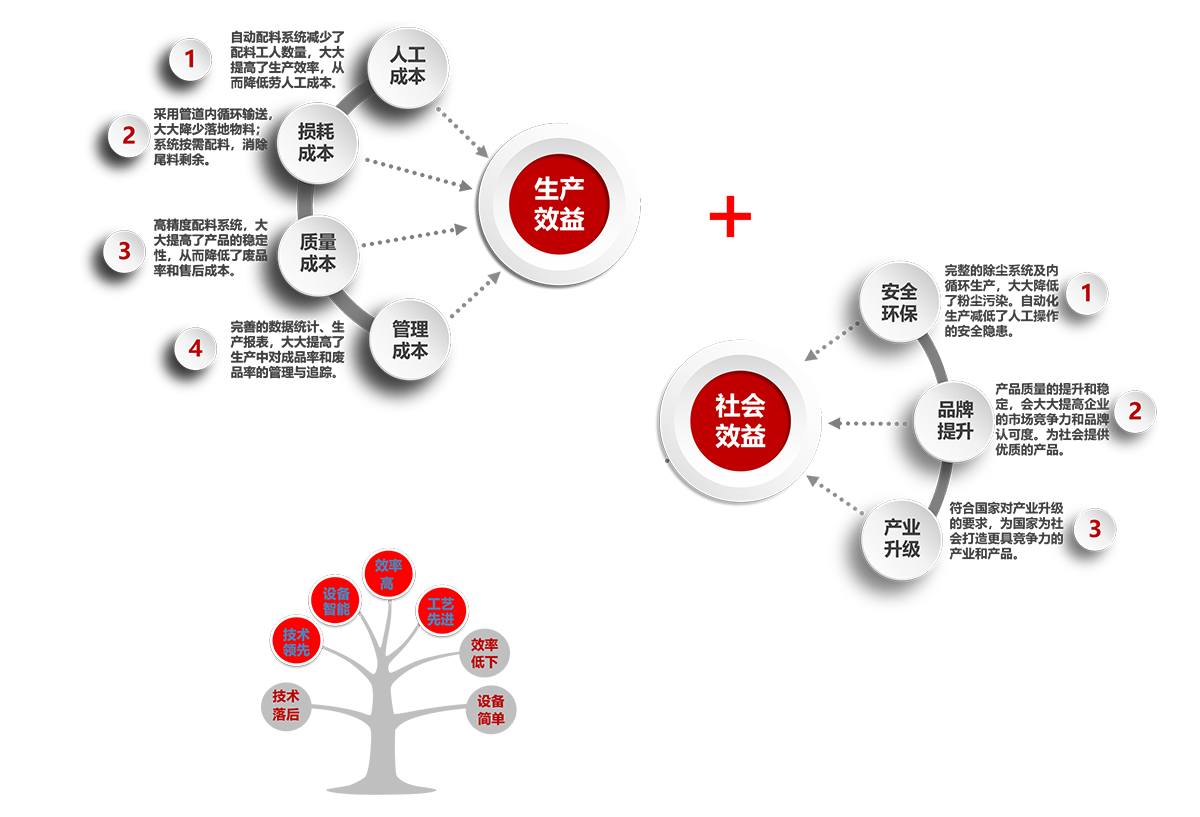

In the plastic processing industry, the centralized feeding system, as an advanced material conveying solution, is widely used in injection molding, blow molding, extrusion and other fields. Our company's centralized feeding system achieves fully automated closed-loop production by improving measurement accuracy and optimizing material conveying processes, thereby enhancing the production efficiency, product quality, and market competitiveness of the entire product chain.

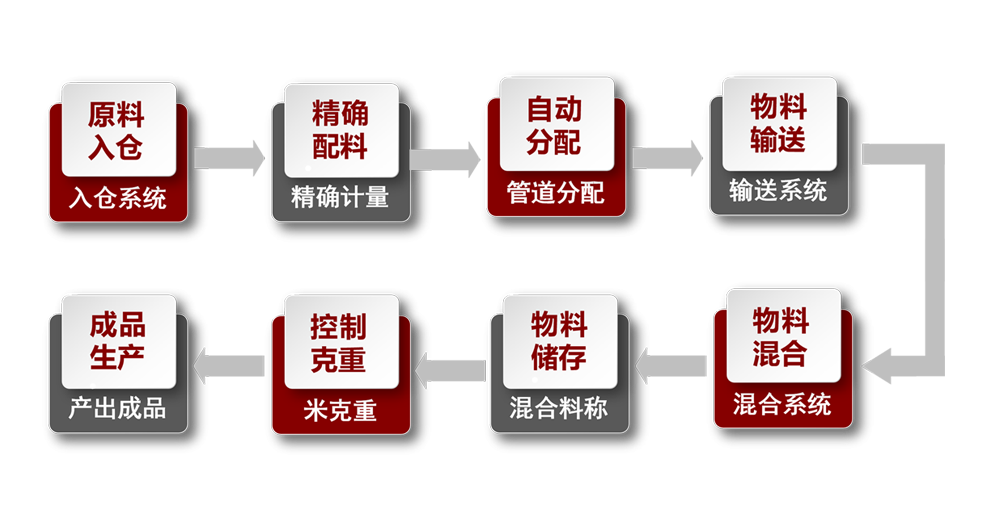

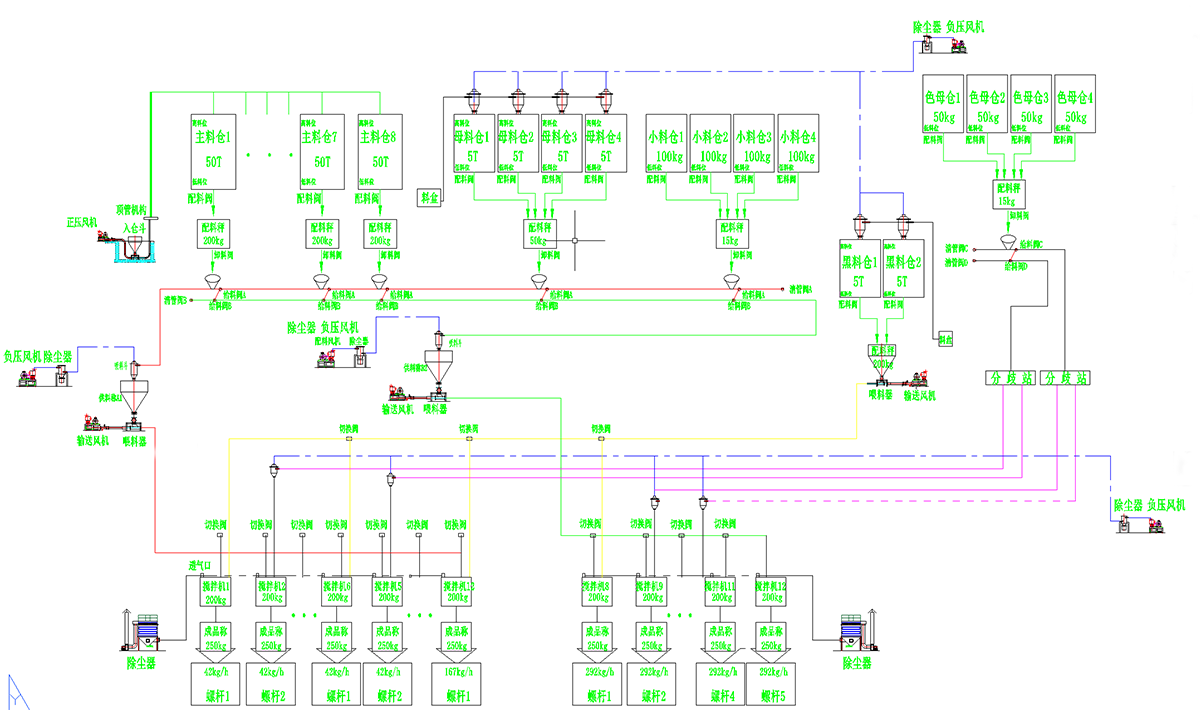

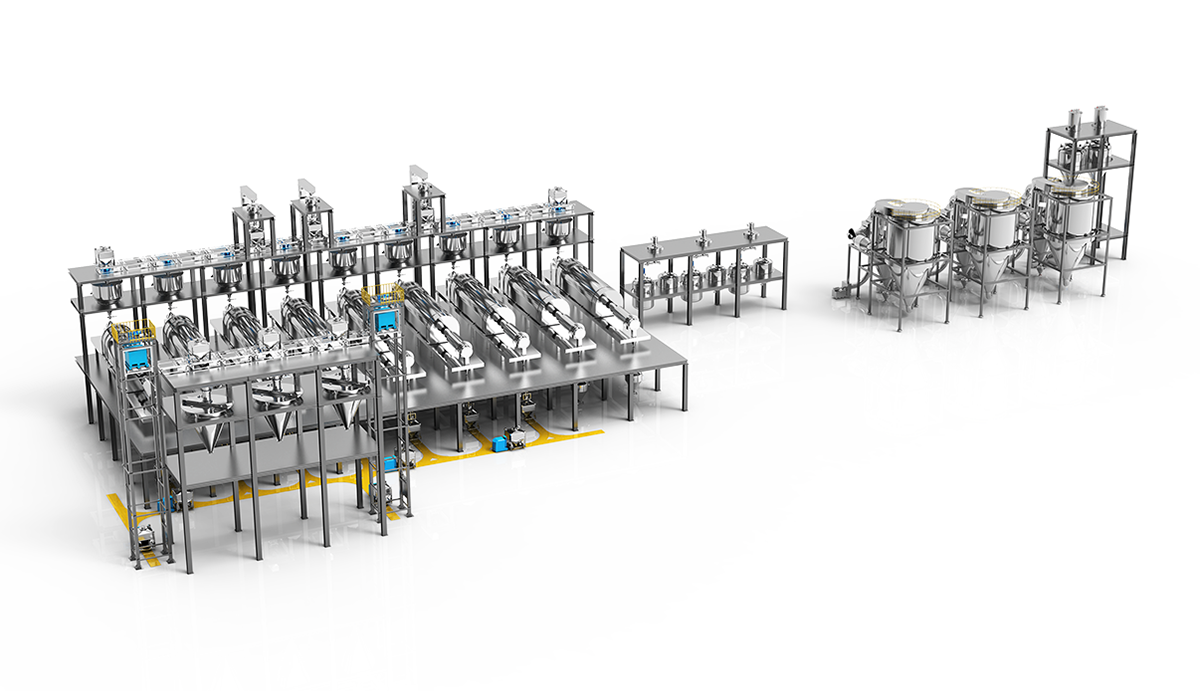

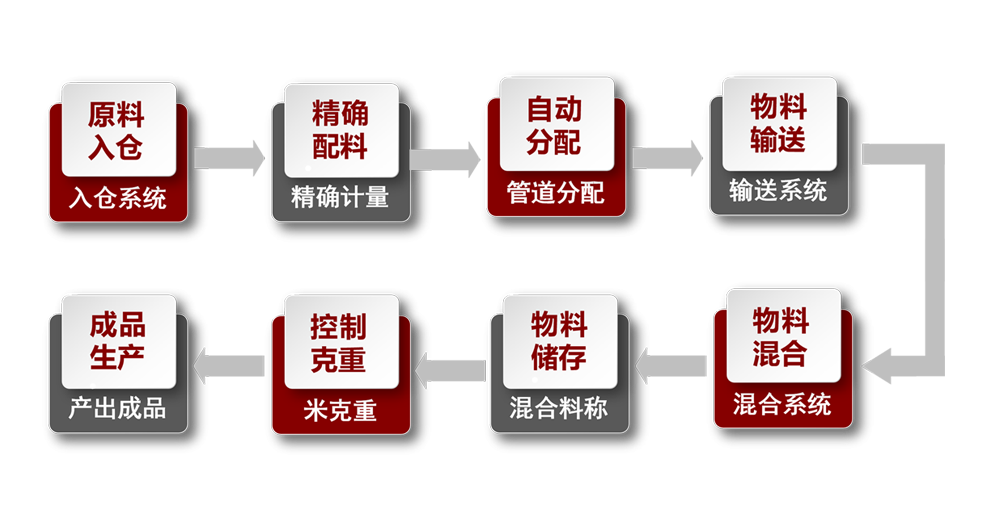

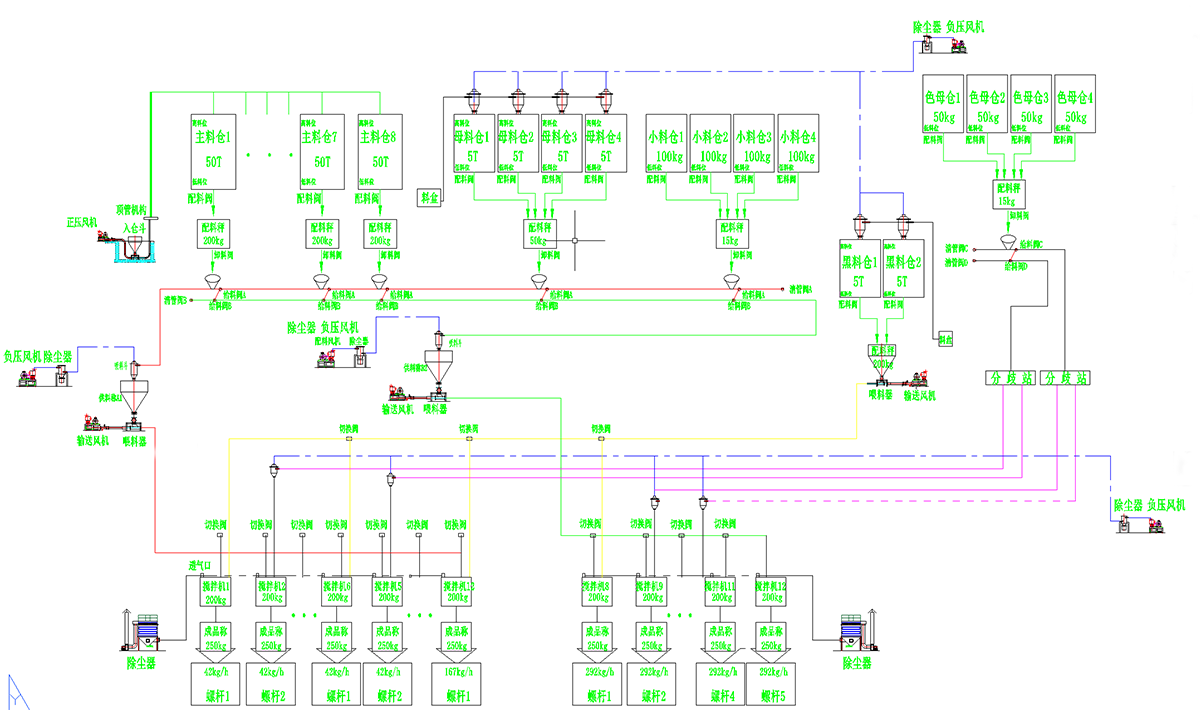

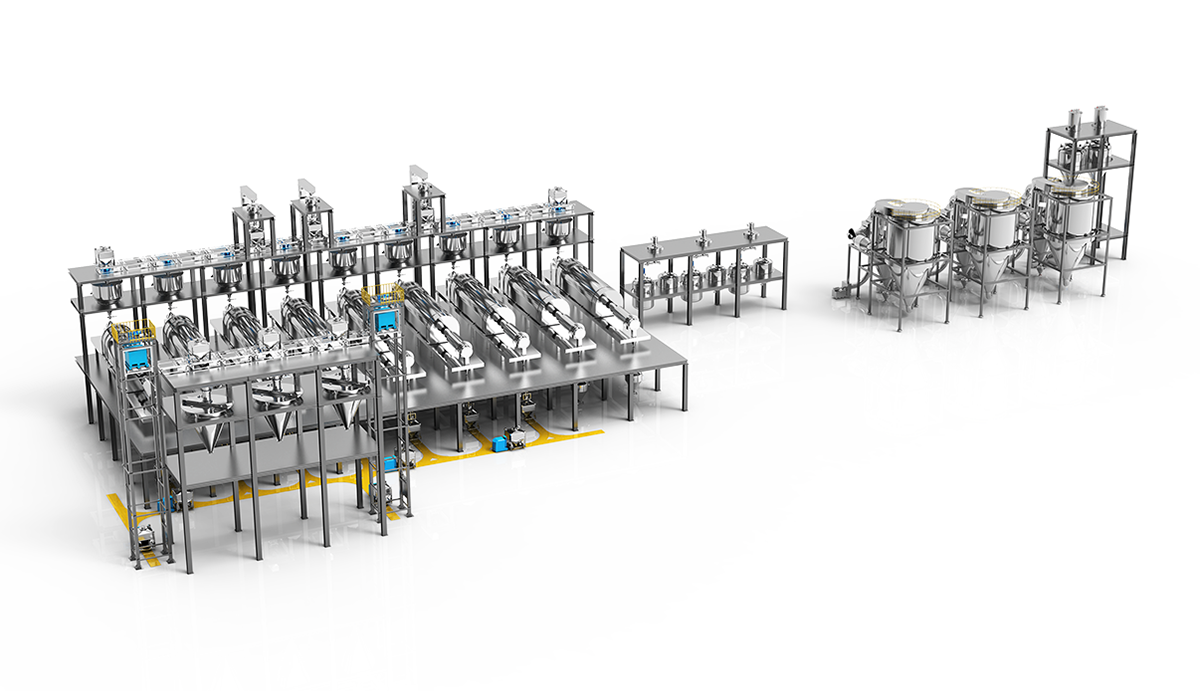

A centralized feeding system is an integrated material management solution that ensures continuous, uniform, and precise supply of materials during the production process by centrally controlling the distribution of materials. The system usually includes components such as storage unit, conveying unit, distribution unit, and control system. The centralized feeding system is an automated auxiliary equipment designed based on the placement of customer on-site units and the use of customer raw materials, combined with advanced auxiliary equipment, which can achieve functions such as centralized warehousing, precise batching, automatic conveying, and uniform mixing, thus realizing a comprehensive solution for intelligent and uninterrupted operation.

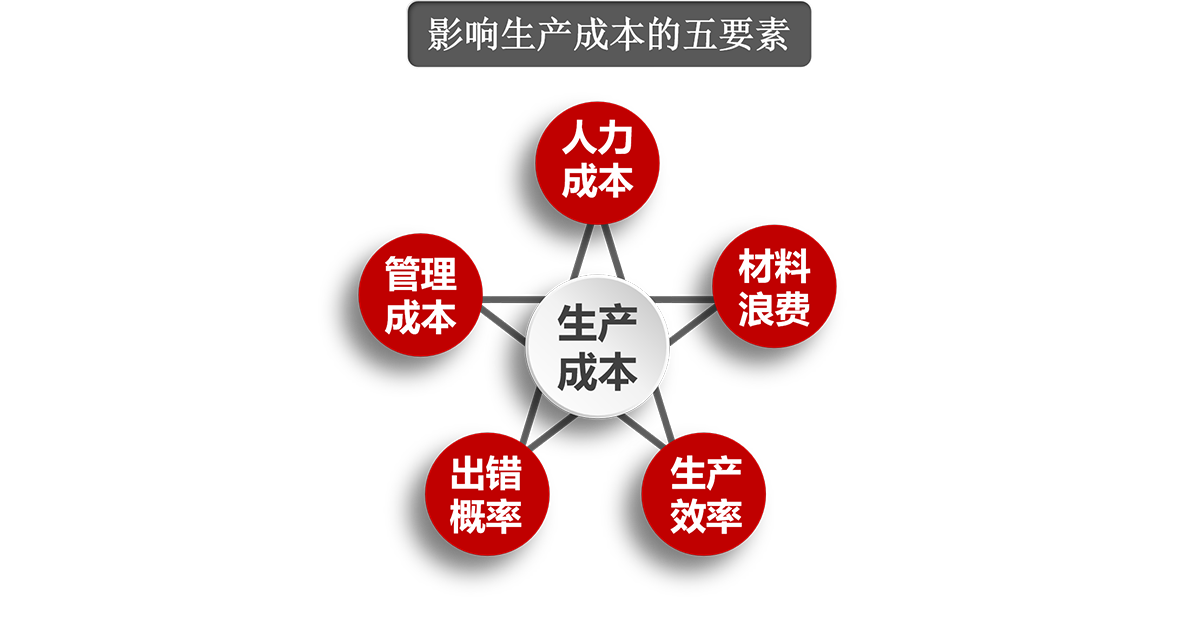

Advantages of our centralized feeding system:

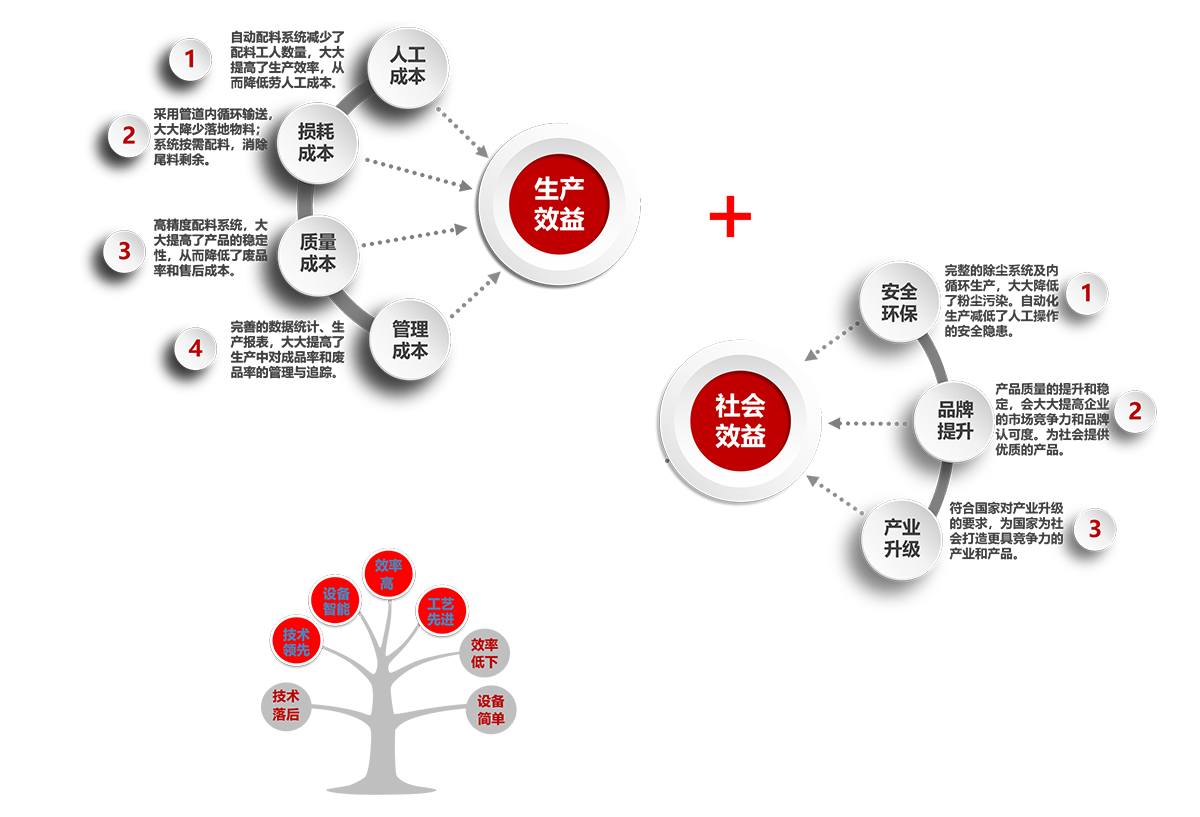

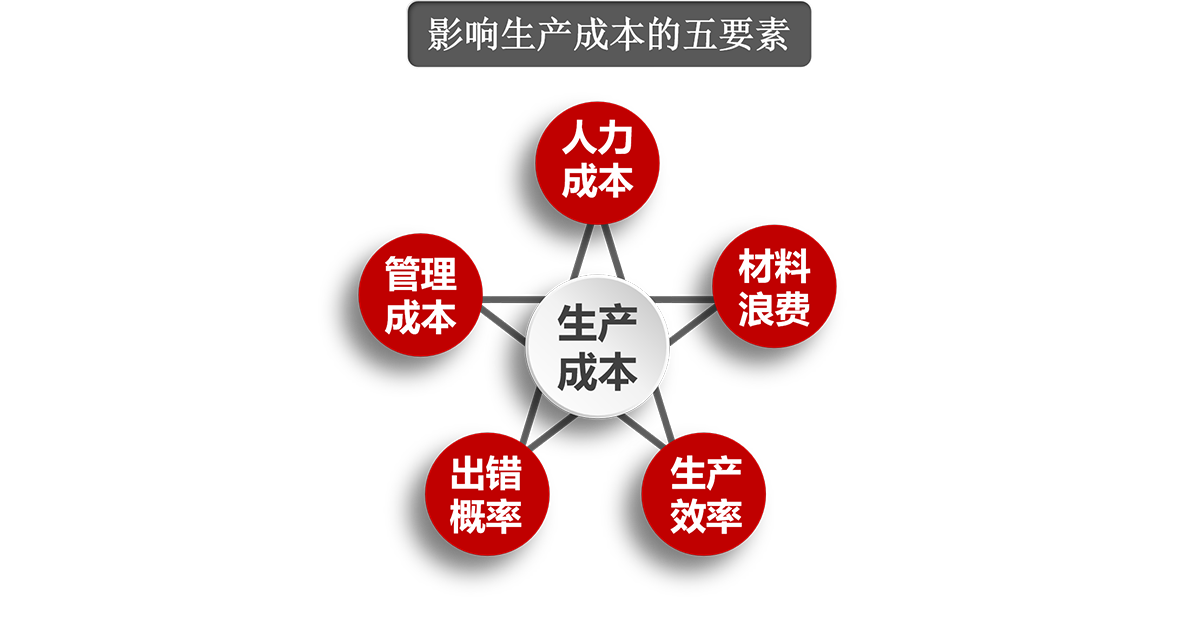

The centralized feeding system can automatically and accurately mix raw materials according to different formulas, ratios, and dosages based on the products of each unit, efficiently and quickly delivering materials to each unit, thus achieving fully automated production. The centralized feeding system adopts industrial computers to automatically control all units, enabling the entire production process to operate fully automatically. The system monitors all operating points and plays a role in detection and correction, making the entire production process stable and reliable. The centralized feeding system can accurately measure the consumption of raw materials, output of finished products, and production losses, and automatically generate spreadsheets and reports, providing data for enterprise management and improving the management level of the enterprise.

Characteristics of our company's centralized feeding system:

Our company's centralized feeding system can provide comprehensive planning for project workshops, raw material storage, transportation, feeding, production, finished product packaging, and storage, offering customers a full range of design solutions. The centralized feeding system can achieve modern, digital, and intelligent management from granulation, raw material feeding, raw material storage, dehumidification and drying, precise metering, conveying system, mixing system, and production unit, thereby ensuring the stability and reliability of continuous production of customer product quality.

Application Fields:

The centralized feeding system can be applied to injection molding, blow molding, extrusion, film production, packaging film production, chemical, pharmaceutical, food, feed, cable auxiliary materials, refractory material production and other industries. Applicable materials include powders, particles, and liquids.

中文版

中文版 English

English