In today's rapidly changing manufacturing and processing industry, efficiency and cost control have become key elements of sustainable enterprise development. The wide application of automation technology undoubtedly provides strong support for the realization of this goal. Among them, as an important part of modern production line, the automatic batching system is gradually becoming the first choice of many enterprises with its obvious advantages of saving labor and reducing cost. The working principle, advantages and application examples of automatic batching system in different industries will be discussed in this paper, so as to provide valuable reference for enterprise decision makers.

Basic principle of automatic batching system

The automatic batching system is an intelligent equipment integrating sensor technology, computer technology, automatic control technology, network communication technology and other high-tech means. The core is to realize automatic weighing, proportioning, conveying and mixing of raw materials through accurate metering device and efficient control system, so as to complete the whole batching process.

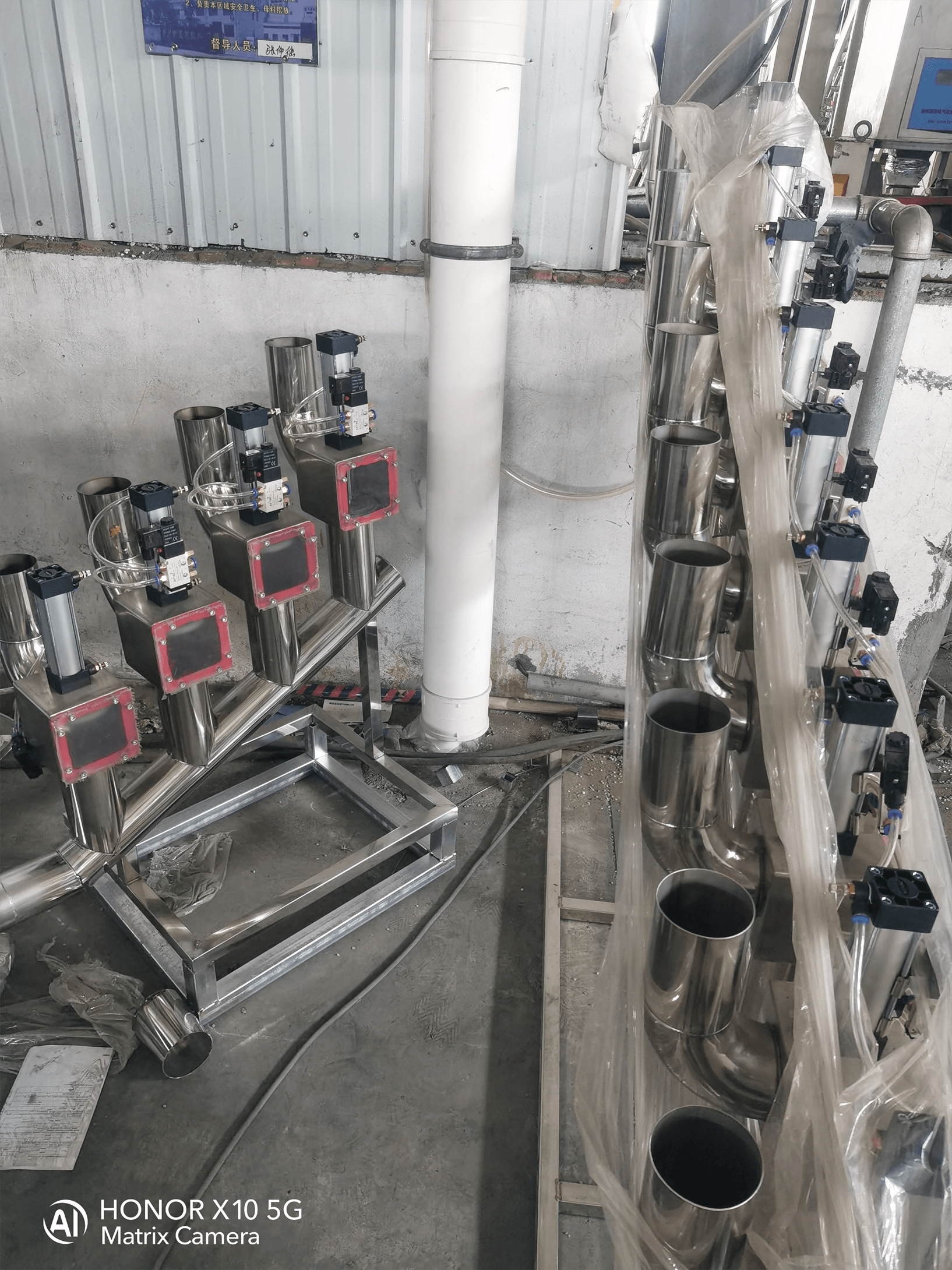

The system usually consists of the following key parts: raw material storage and conveying system, metering device (such as electronic scale), control system (PLC or DCS), mixing device and monitoring system. Raw materials are accurately sent to the metering device for weighing through conveying equipment (such as screw conveyor and belt conveyor). The control system automatically adjusts the conveying capacity of each raw material according to the preset formula to ensure accurate proportioning. The prepared raw materials are then sent to the mixing plant for thorough mixing to produce a satisfactory finished product. During the whole process, the monitoring system records and feeds back various data in real time to ensure the stability and traceability of the batching process.

中文版

中文版 English

English