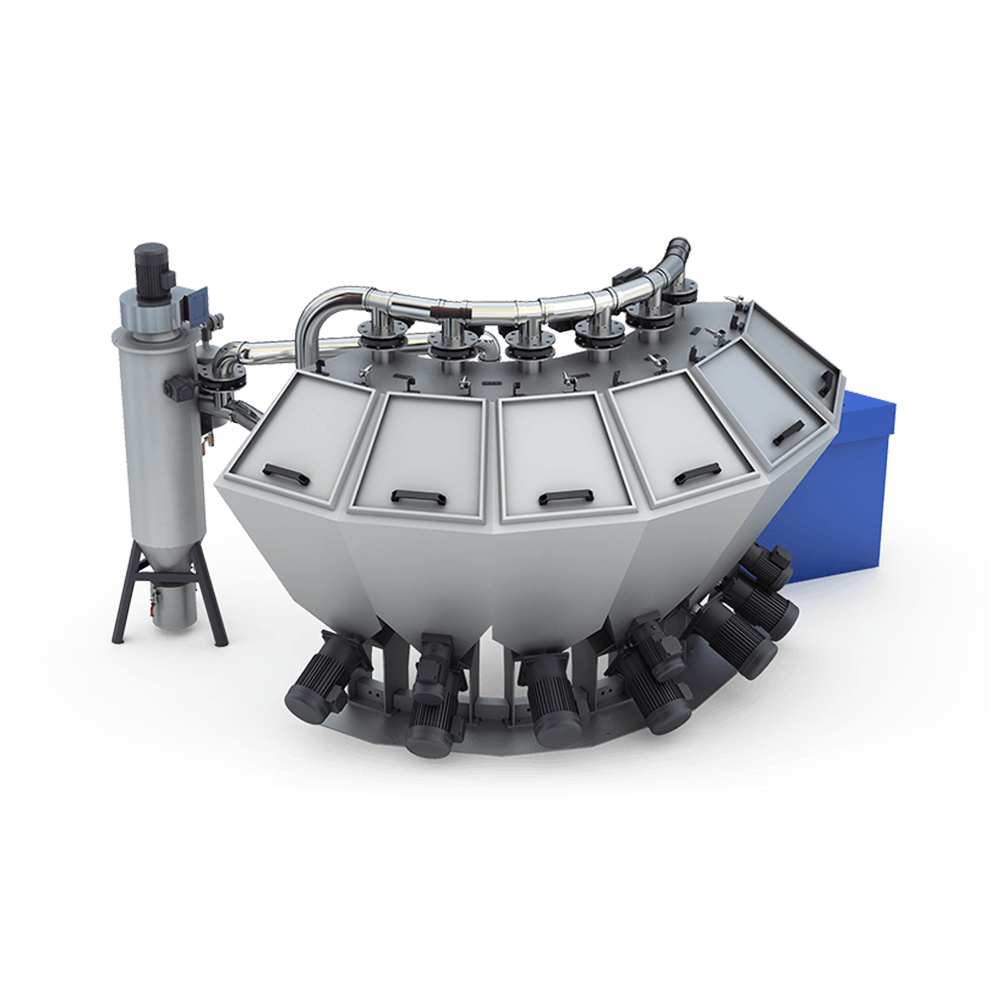

1 Precision measuring system Scope of application:

Mainly used in rubber and plastic, chemical, pharmaceutical, food and other industries, for the use of less functional masterbatch, additives, small materials and other functional materials accurate measurement and transportation. It can guarantee the stability of product quality and reduce labor and waste.

Composition of precision measurement system:

1. Master material storage bucket N;

2. N sets of masterbatch disperser;

3. Small material spiral N pieces;

4. High precision measurement weighing 1;

5. 1 high-performance conveying pump;

6. 1 set of conveying pipeline;

7. Electric control system 1 set;

8. 1 set of steel structure platform;

9. Cable air circuit.

Precision measuring system Features:

1. High measurement accuracy;

2. Conveying without residue;

3. Integrated into the operating system to achieve fully automatic production;

4. In the conveying process, the material is dispersed and sprayed into the mixer to make the mixing faster and more uniform.

2. Measurement principle:

According to the total mass of the mixing material storage hopper (bin) (including material weight and leather weight), the minus mass is used as the weighing device of the mixing material amount.

中文版

中文版 English

English